Memory Foam in the Operating Room: Marketing vs Reality

There is a significant misconception regarding the effectiveness of memory foam in operating room environments.

We believe its use in surgical mattresses, has increased pressure injury risks to patients. It’s physics, not marketing.

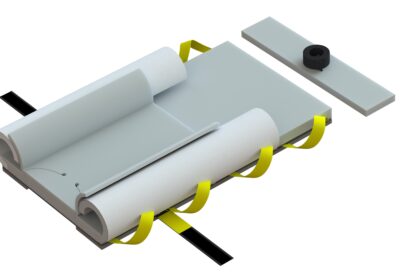

One of the primary concerns we observe with positioning platforms made from memory foam is its inadequate pressure management capabilities, especially 1 inch thick pads. This issue becomes particularly evident when routine safety products are placed between the memory foam and the surgical mattress, as this breaks transmural offloading. The foam often compresses nearly 90%, lacking the necessary rebound for proper pressure management, which is influenced by factors such as density and indentation load deflection (ILD). Additionally, memory foam is frequently unreinforced, making it susceptible to tearing and bunching, causing pressure and shear injuries.

This leads us into its impact when embedded in surgical mattresses, as all effective heat conduction from the patient’s warmth is impeded due to everything between it and the patient. Memory foam’s behavior ties closely to its glass transition temperature (Tg), a key property of the polyurethane it’s made from.

Let’s break it down:

🧪 Glass Transition Basics

The glass transition is the temperature range where a polymer—like the viscoelastic polyurethane in memory foam—shifts from a hard, glassy state to a softer, rubbery one. Below Tg, the material’s molecular chains are locked in place, making it stiff. Above Tg, those chains gain enough thermal energy to move, so the foam gets pliable and can mold to pressure (like your body). For memory foam, this isn’t a sharp switch but a gradual change, which is why it feels temperature-sensitive.

🤔 How It Works in Memory Foam

Memory foam’s Tg is typically engineered to be near or slightly below room temperature—say, ~70°F (21°C), though it varies by formulation. When it’s cold (below Tg), like in the OR, the foam feels firm because the polymer chains can’t slide past each other easily. As it warms up—say, from your body heat at 98.6°F (37°C)—it crosses that Tg threshold. The chains loosen up, the foam softens, and it conforms to your shape. Once the pressure’s off and it cools down, it slowly returns to its original form, giving that “memory” effect.

💥 Temperature’s Role

Temperature directly messes with this. In a chilly room (below 60°F or so), memory foam can feel like a brick—slow to respond and less cushy. That’s why some folks say their mattress feels off in winter. On the flip side, in a hot room or under a heavy blanket, it gets too soft, even mushy, because it’s well above Tg. This is also why heat buildup is a downside: your body keeps it in that rubbery state, and it doesn’t “breathe” well to cool off.

This is why effective pressure management & research needs to be measured on a temperature curve, paying close attention to all the products placed between it and the mattress.

We can help!

#HAPI #AORN